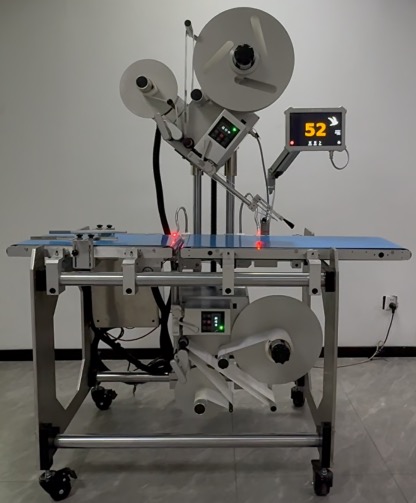

In the evolving food packaging industry, food packaging has become an important method for preserving freshness and extending shelf life. However, effective labeling on flexible packages and films remains a challenge due to differences in package size, label placement and production capacity. COTAO CONUS 1102 Top-Bottom Packaging Printer offers a flexible, reliable and fully customizable solution that can be tailored to the specific needs of food manufacturers using flexible packaging. Whether top labeling, bottom labeling, with or without printing, the CONUS 1102 easily adapts to the needs of modern production lines up to 45 ppm (package per minute).

Built for Diverse Labeling Scenarios

The CONUS 1102 is an integrated servo-controlled wipe-on printer applicator that is compatible with both printed and overprinted label applications. It is suitable for handling top or bottom labeling of various tray, bag, flexible package or film sizes and is commonly used for packaging baked goods, meats, seafood, prepared foods, beverages, dairy products or other foods. Its manually adjustable height handle enables the operator to readjust the labeling height in seconds, ensuring accurate label positioning regardless of product thickness or line variations.

Flexibility is the Core Advantage

The system can operate in full print-and-apply mode or apply labels, depending on user needs. The CONUS 1102 features servo-printing technology, allowing traceability, compliance, and visual branding to coexist seamlessly.

Keywords: food packaging printer, CONUS 1102 Top-Bottom Packaging Printer, Top labeling, Bottom labeling, Wipe-on printer applica,45 PPM